These thickness gauges are especially handy for measuring thickness of small parts, metal, rubber, vinyl, paper, foil and other sheet material.

- The objects to be measured is clamped by simple lever operation. The measured values are read directly on the dial gauge.

- Since the anvil and the contact point are adjusted for parallelism, accurate measured values are obtained.

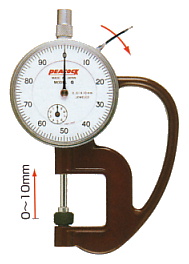

Dial Thickness Gauges 0.01mm type

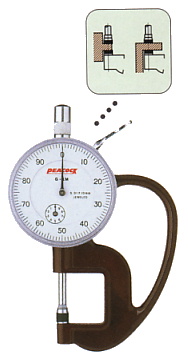

anvil (ceramic)  |

anvil (metal)  |

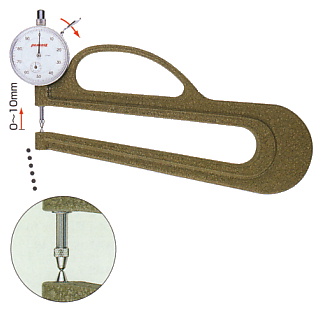

anvil (metal) is cut, which facilitates measurement in a narrow place.  |

||||||||||||||||||

anvil (ceramic)  |

anvil (ceramic)  |

|

|

|

|

|

PG-10 Paper Gauge

A PAPER GAUGE “PG-10” is a Thickness gauge to the Measurement of Paper and similar objects.

| Model | PG-10 |

| Graduation | 0.01mm |

| Range | 0 – 10mm |

![]() Thickness Gauge to the Measurement of Paper

Thickness Gauge to the Measurement of Paper

and Similar objects.

![]() The gauge is calibrated in 0.01mm or 10 micron.

The gauge is calibrated in 0.01mm or 10 micron.

Portable size! Excellent usability!

The SK material is used for the

parts holding paper in between

- The gauge graduation is represented in millimeter and micron.

- Contact Point and Anvil parts available in special geometry at request.

Specifications

| Model | Graduation (mm) |

Range (mm) |

Throat depth (mm) |

Accuracy (µm) |

Contact Point | Measuring force less than (N) |

||

| Dia (mm) | Parallelism (µm) | |||||||

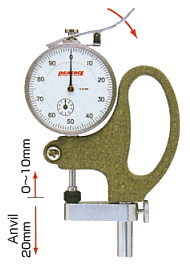

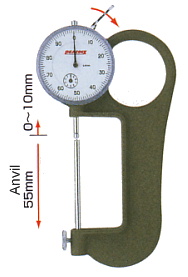

| G | 0.01 | 0 – 10 | 20 | ±20 | 10 | 5 | 1.8 | |

| G-MT | 0.01 | 0 – 10 | 20 | ±20 | 10 (metal) | 5 | 1.8 | |

| G-1A | 0.01 | 0 – 10 | 20 | ±20 | 5 | 5 | 1.8 | |

| G-1M | 0.01 | 0 – 10 | 20 | ±20 | 6 | 5 | 1.8 | |

| PG-10 | 0.01 | 0 – 10 | 20 | ±20 | 10 (metal) | 5 | 1.8 | |

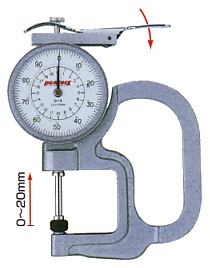

| G-2 | 0.01 | 0 – 20 | 33 | ±22 | 10 | 5 | 2.0 | |

| G-3 | 0.01 | 30 (Anvil 20mm) | 20 | ±20 | 10 | 5 | 1.8 | |

| G-4 | 0.01 | 65 (Anvil 55mm) | 30 | ±20 | ball tip | — | 1.8 | |

| H | 0.01 | 0 – 10 | 120 | ±20 | 10 | 5 | 1.8 | |

| H-MT | 0.01 | 0 – 10 | 120 | ±20 | 10 (metal) | 5 | 1.8 | |

| H-1A | 0.01 | 0 – 10 | 120 | ±20 | 5 | 5 | 1.8 | |

| H-2 | 0.01 | 0 – 10 | 170 | ±20 | Spherical | — | 1.8 | |

| H-3 | 0.01 | 0 – 10 | 170 | ±20 | Spherical | — | 1.8 | |

Dimensions

Dimensions; G  |

Dimensions; G-MT, PG-10  |

Dimensions; G-1M  |

Dimensions; G-1A  |

Dimensions; G-2

Dimensions; G-3  |

Dimensions; G-4  |

Dimensions; H

Dimensions; H-1A

Dimensions; H-MT

Dimensions; H-2

Dimensions; H-3